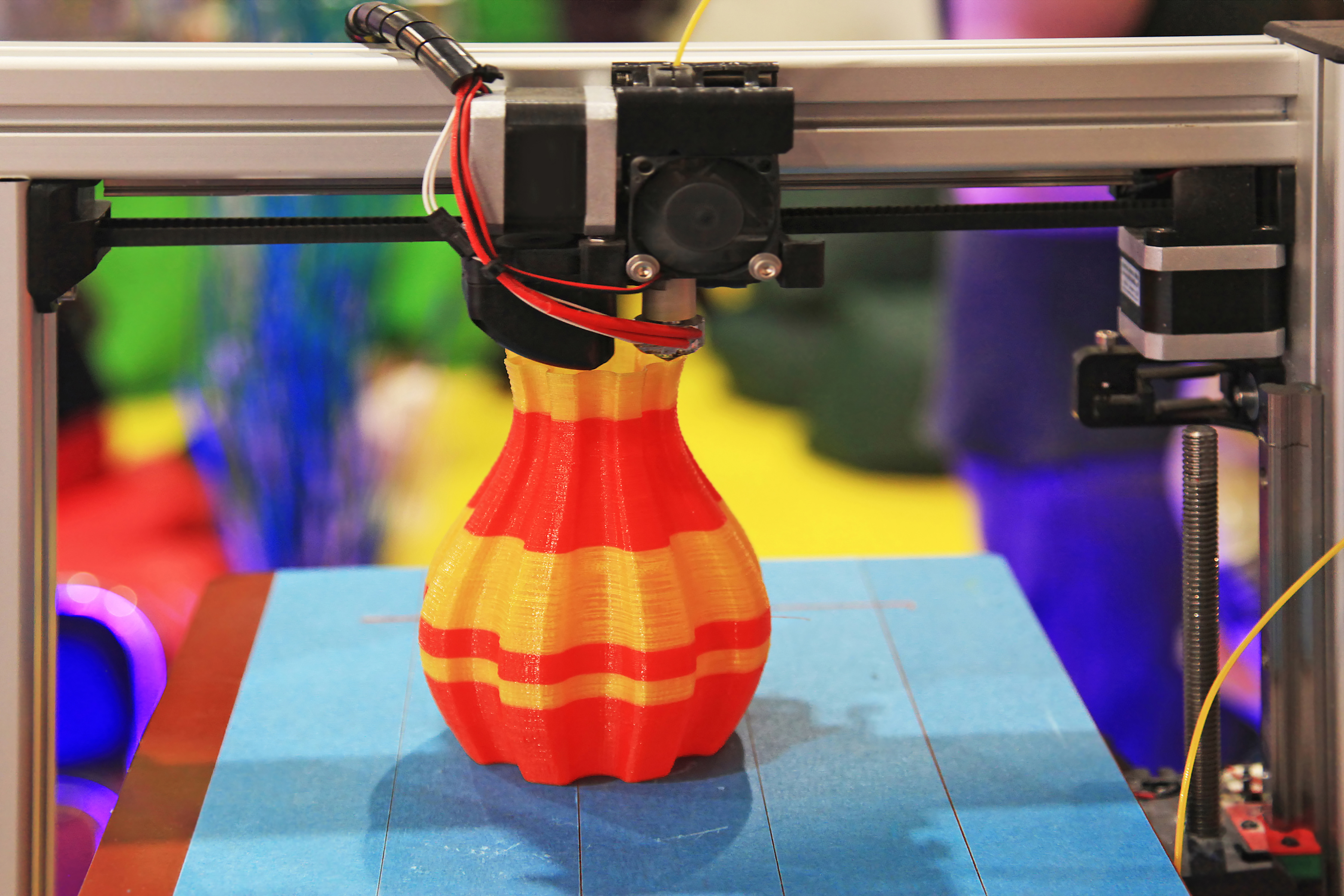

The digitisation of manufacturing or the fourth industrial revolution, is reorganising manufacturing and supply chains. Industry 4.0 technologies such as automation and robotics are set to make industrial processes more efficient, but it is 3D printing that has the potential to restructure them entirely.

Whilst 3D technology itself has been around for decades, the 3D printing market today is a very different place. Our latest Executive Briefing report: Additive action: 3D printing as an accelerator for digital manufacturing, examines recent market developments and identifies the opportunities and potential of 3D printing as a key enabler of Industry 4.0.

3D printing technology has undergone seismic change over the past few years, progressing from primarily being used for prototyping, to actual production. Due to improved economics, manufacturing accuracy and predictability, 3D printing is gradually approaching the point where it can compete with traditional manufacturing methods for certain applications. Now, at the precipice of its next phase of maturity, the sector is undergoing further massive transformation – shifting from low volume production to full scale, digital manufacturing.

New entrants push innovation

Major patent expiries since 2009 resulted in new players entering the market, making 3D printers affordable for the first time. More recently we have seen traditional print manufacturers including HP, Xerox and Ricoh enter the additive space. Their arrival was a worry for the incumbents, as these deep-pocketed giants could deploy billions in gaining the technological edge – this in turn forced all manufacturers to push the innovation envelope harder than ever.

The rapid evolution within the additive manufacturing (AM) industry has involved radically different approaches to market, ranging from HP’s huge capital investment in proprietary additive technologies, to M&A-focused strategies and everything in between.

3D printing as a way of making products such as luxury goods, footwear and sports protective gear, in a more cost-efficient, quick and sustainable manner, has been rapidly adopted. Businesses can see the latent opportunity that additive provides to meet customer needs through digital manufacturing. For industrial applications within the aerospace, automotive and medical arenas, manufacturers are leveraging the technology to do prototyping in-house, thus realising sizable savings across R&D, tooling and capital costs, as well as reducing the time to market due to the ability to make adjustments and incorporate feedback immediately.

AM technologies will continue to grow in importance

Undoubtedly the role of additive manufacturing technologies will continue to grow in importance as technological development continues to refine existing applications and expand possibilities for new ones. However, it is important not to misinterpret this rapid growth as a universal sign that additive manufacturing technologies are being adopted across all industries at an equal pace.

Whilst it’s clear that the potential to change the way in which products are made, from conception to implementation and delivery, will have far-reaching impacts on business ecosystems, technological convergence and sustainability, these changes will not happen overnight.

There is uncertainty around regulation – largely due to the fundamentally different way 3D printed parts are constructed. Worker expertise is another concern – the new design paradigm will require new talent pools if the complexity and functional possibilities are to reach their true potential. There are also the long-term cost horizons for mass manufacturing to be factored into the decision-making process.

Moreover, the growing array of additive technologies and materials has made the landscape increasingly confusing for business leaders and investors, who are weighing up integrating additive manufacturing into their existing production processes and creating entirely new ones.

Requires a well-informed and systematic approach

From both a supply chain and sector perspective, the importance of a well-informed and systematic approach to developing a 3D printing strategy is paramount. A pure technological focus will not be enough to succeed in this emerging industry. 3D printing requires a change in thinking and working with the right people with the right approach is critical to exploit the technology’s full potential.

Entrepreneurs, investors, business owners and C-suite executives alike must take a holistic view of the market and analyse risk versus reward in the context of market niche and position. In order to successfully tap into the cost savings, increased flexibility and shorter time to market these new technologies can provide, a thorough understanding of the market trends and drivers is a pre-requisite.

At the same time, OEMs must monitor market innovations and trends to ensure the rollout of new technologies, acquisitions and partnerships are correctly oriented towards achieving high-growth areas of industry.

Learn more about Quocirca’s Executive Briefing Report on 3D Printing or download the free Executive Summary.